Intralogistics ULMA pallet conveyor Neetwk

ULMA Conveyor Components S. Coop., established in 1958, it is part of the ULMA Group. ULMA Conveyor Components advances towards the future committed itself to the continuous improvement, on-going innovation and customer's satisfaction, focusing its business strategy on the creation of wealth for its natural environment and provision of employment.

ULMA Conveyor Components signs a collaboration agreement with REMA TIP

At ULMA Handling Systems, we offer a wide range of conveyor and automatic guided vehicles, such as VTD, STV, AGV, motorised transport, gravity transport, turning tables, transfers, lifts, motorised curves, etc. Conveyor and automatic guided vehicles are used fundamentally to cover the needs of transporting loads between various points.

ULMA Conveyor Components. Phosphate handling in Jordan ULMA Conveyor

Comprehensive, interoperable, artificial intelligence-based solutions, with the mission of improving the efficiency and sustainability of today's healthcare systems. ULMA is one of the largest Business Groups in northern Spain and maintains a clear commitment to Innovation, Employment and Added Value.

.jpg?quality=85&type=webp)

Ulma Atlanta High Tech flowpack machine with Dakota Infeed conveyor

ULMA Conveyor Components designs, manufactures and sells components for the bulk handling industry like rollers, garlands, idlers and pulleys, mainly for the mining, power plants, cement and steel mills sectors. Rollers Pulleys Garlands Idlers NEWS December 14, 2023

Ulma PV350 LSHIX flowpacker with conveyor belt • Duijndam Machines

With this new website, www.ulmaconveyor.com, ULMA Conveyor Components pools knowledge and technical solutions that are largely the result of close collaboration between its highly-qualified engineering team and each of its customers, and this experience may clearly be very valuable to potential customers working in similar sectors. Previous Next

.jpg?quality=85&type=webp)

Ulma Atlanta High Tech flowpack machine with Dakota Infeed conveyor

ULMA'S conveyors are designed under the strictest quality standards in all the components and processes. Benefits of pallet conveyors: High flexibility Broad range, designed for all functionalities, including extreme/harsh environments Solid, long useful life Easy to maintain Low noise emissions Easy assembly of accessories (tops, photocells, etc.)

Roller conveyor ULMA HANDLING SYSTEMS for cargo / modular / for airport

The e.scala® system by stow Robotics is a three-dimensional modular ASRS for containers without the need for conveyors, lifting devices or sequencers, where the robots move in all three dimensions via a ramp system.. The Atlas 2D by stow Robotics is a two-dimensional modular pallett storage systems without the need of conveyors or sequenzers, where the robots move in two dimension and change.

.jpg?quality=85&type=webp)

Ulma PV350 LSX flowpacker with Eurolock • Duijndam Machines

April 20, 2023 Taking the temperature of the Chilean market ULMA Conveyor Components starts the year 2023 with the installation of a roller monitoring system in one of the most important copper mines in northern Chile.

ULMA Conveyor Components signs a collaboration agreement with REMA TIP

Así fue como Eiffel acabó llegando a Ulea, alojándose en la casa del exportador de frutas y visitando el balneario casi a diario en cada una de sus visitas. Y fruto de esa amistad y esas visitas fue como surgió la idea de construir una casa en Ulea, diseñada por él mismo. Esta casa se conoció como la "Casa de París», por los negocios.

Intralogistics ULMA pallet conveyor Neetwk

Fully automated and flexible conveyor and automatic guides vehicle that does not require any human intervention. What is an Automated Guided Vehicle or AGV?. ULMA Handling Systems Bº Garagaltza, 50 Apdo 67 -20560 OÑATI- Gipuzkoa. T. +34 943 782 492 F. +34 943 782 910 View on Google Maps.

ULMA Conveyor Components invierte en un nuevo centro de mecanizado para

ULMA's automated warehouse systems allow controlled temperature storage considering the safety and traceability of the product, which are parameters of vital importance. We have our own logistics model aimed at large, medium and small companies in the supermarket and retail sector that decide to make a commitment to their logistics efficiency.

.jpg?quality=85&type=webp)

Ulma PV350 LSHIX flowpacker with conveyor belt • Duijndam Machines

ULMA Conveyor Components originally called Cooperativa Industrial de Ochandiano. The cooperative, under the name of ROCHMAN, S. Coop., was created by the first work communities established in the Otxandio region. It was officially registered with the Ministry of Labour, and little by little acquired full legal existence.

ULMA Conveyor Components S. Coop. “Más de cuarenta años transportando

At ULMA we are constantly evolving and planning towards the logistics systems of the future. Innovation and personal and professional commitment to our customers are our guiding lights.. Conveyor and check-in belts: 3 different configurations with 1, 2 or 3 conveyor belts; Tubular frame-mounted conveyor belts; Plug & Play conveyor belts.

Nuestra empresa ULMA Conveyor Components

ULMA Conveyor Components offers a wide variety of rollers for the bulk and unit handling industry to the mining sector, power or cement plants and quarries.

ULMA Conveyor Components — English

ULMA Conveyor Components, as part of the manufacturing process improvement plan it is currently involved in, has incorporated a new machining centre into its HDC line with the aim of eliminating the time lag between the manufacture of the roller shaft and the rest of its operations. A key action for the production chain of the product in which.

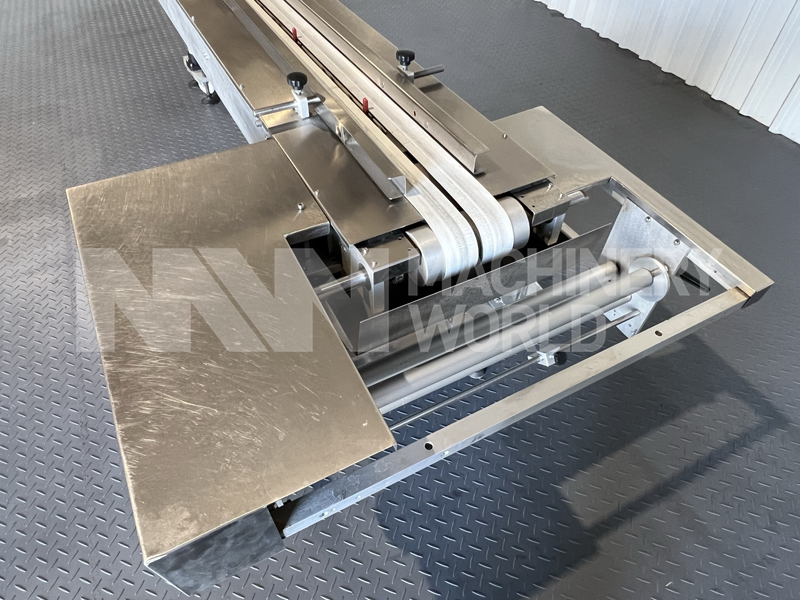

Ulma PV350LSCIX Flowpacker with Conveyor Machinery World

ULMA'S conveyors are produced with the strictest quality standards in all the processes and components. Benefits of lightweight load conveyors Modularity in the design; highly flexible High flow rates, up to 2500 boxes/hour Highly efficient Easy to maintain, with reduced maintenance times Easy assembly of accessories (tops, photocells, etc)